Bulletin 20: Suction and Line Heaters

R.W. Holland, INC.

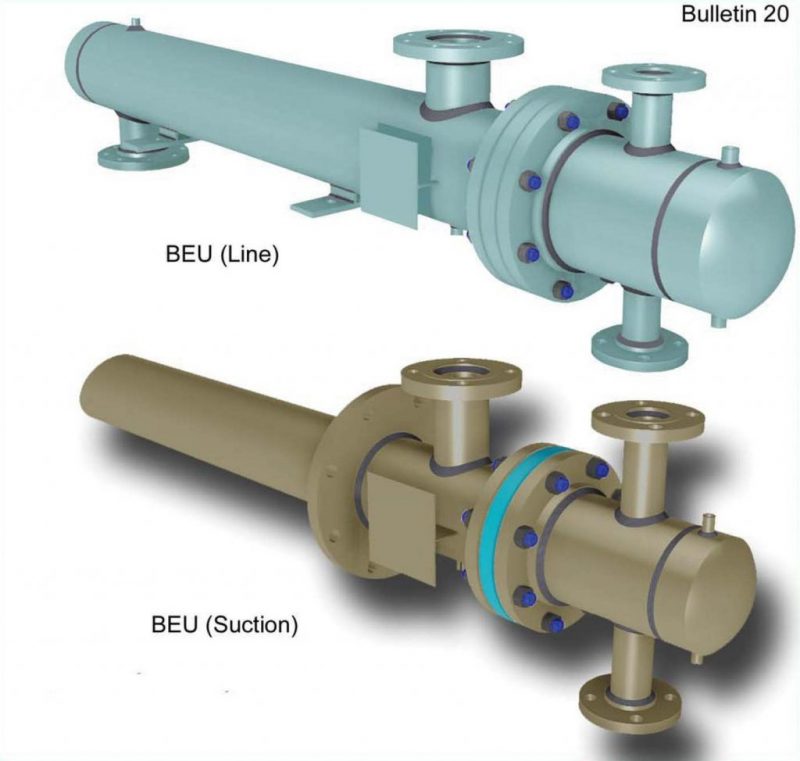

Beu Line & Suction Heaters

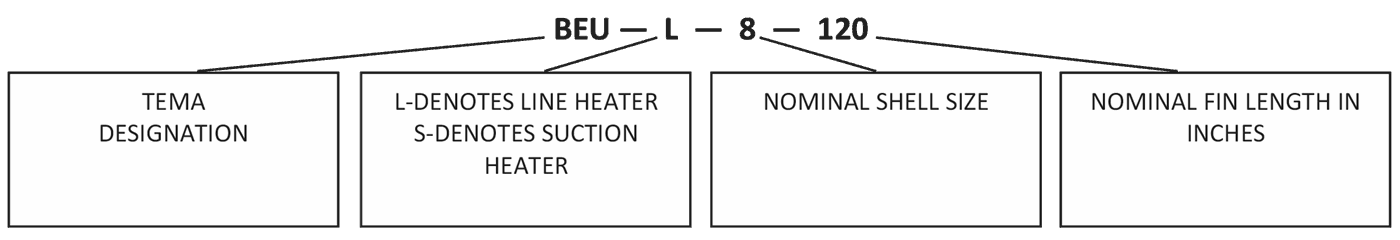

NOMENTCLATURE

The R.W. Holland nomenclature follows TEMA standards where practical. This is shown below.

APPLICATIONS

R.W. Holland line and suction heaters are used in heating heavy viscous fluids (e.g. #6 fuel oil, heavy crude, asphalt etc.). Suction heaters heat the fluids directly from the tank to temperatures suitable for pumping. Line heaters, mounted in line, heat the fluids to processing or burner temperatures. Steam is generally the heating medium however hot water, hot oils, or heat transfer fluids can also be used.

HIGH EFFICIENCY

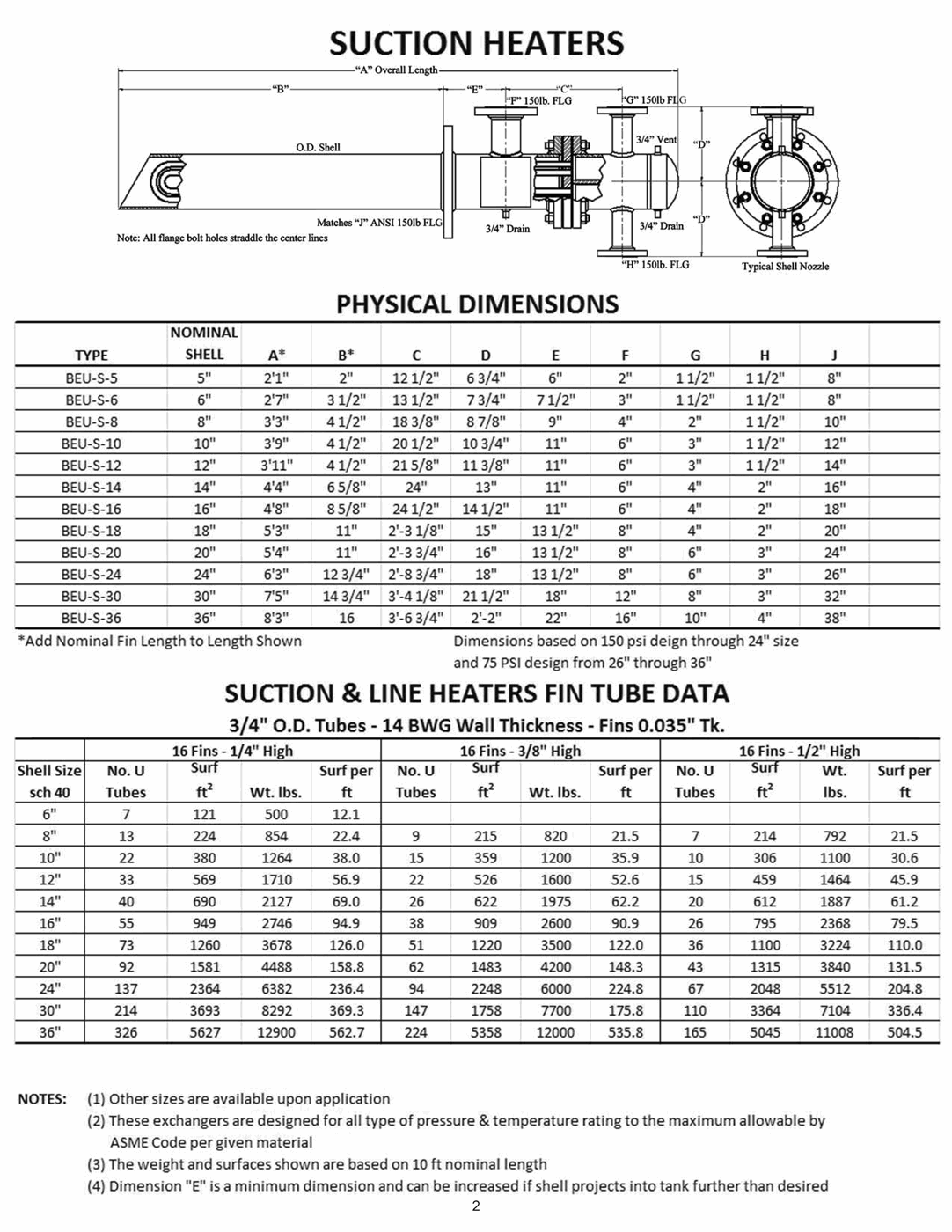

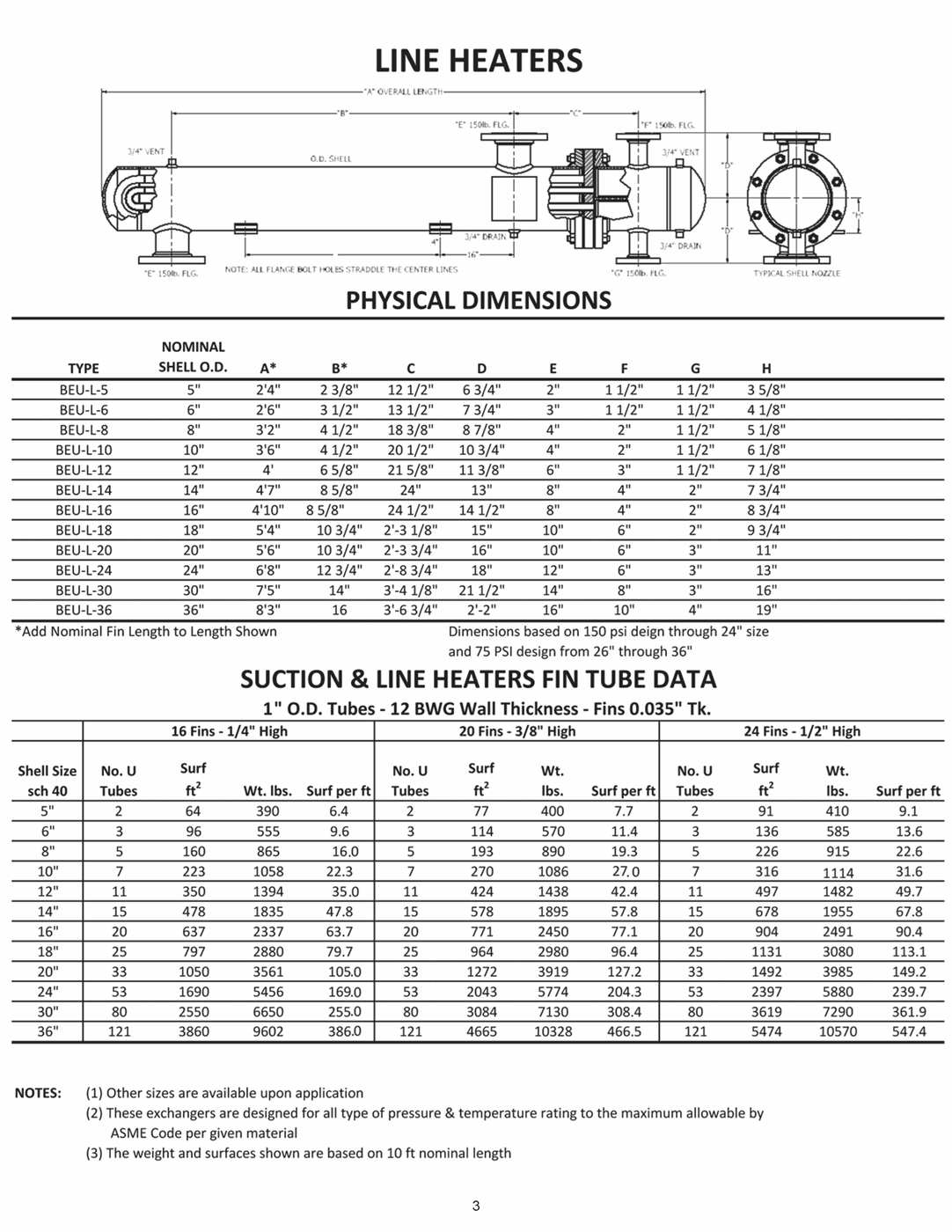

These heaters obtain high efficiency as they utilize the R.W. Holland Petrofin fintube. This is a longitudinal fintube with the fins resistance welded to the tube. Several different tube and fin configurations are utilized to obtain the most economical selection for a specific application. These are detailed in the tables on pages 2 and 3. The use of fintubes keep the metal temperature lower, resulting in less fouling; therefore, extending the period between shut downs for cleaning.

CONSTRUCTION

R.W. Holland line and suction heaters are fabricated in accordance with the ASME unfired pressure vessel code and TEMA standards. Tubesheets are fully studded allowing the removal of the channel for tube inspection without disturbing the shellside closure. This eliminates the need to drain tanks, in the case of suction heaters or piping, in the case of line heaters. Materials of construction are of the highest quality available. Dimensions for standard units are given in the tables on pages 2 and 3.

PRESSURE – TEMPERATURE RATING

Standard ratings are 150 psig at 500˚F for both the shell and tubeside of line heaters and tubeside of suction heaters. The shellside of the suction heater is not pressure rated. Since there is no pressure in the storage tank, pressure rating is not required. Normally, the inlet end of suction heaters is not flanged, preventing the hydrostatic testing of the shellside. Both line and suction heaters can be designed for higher pressure to meet specific applications.

SPECIAL DESIGNS

R.W. Holland can incorporate special requirements to meet a customer’s specific needs. Nozzle and orientation can be changed to match customer piping requirements. Suction heaters can be provided with a flanged inlet connection to match a customer supplied valve that can be operated via an extension from the tank roof. This allows the tube bundle to be removed without draining the tank. Flapper valves can also be fabricated on the heater itself and accomplish the same purpose.

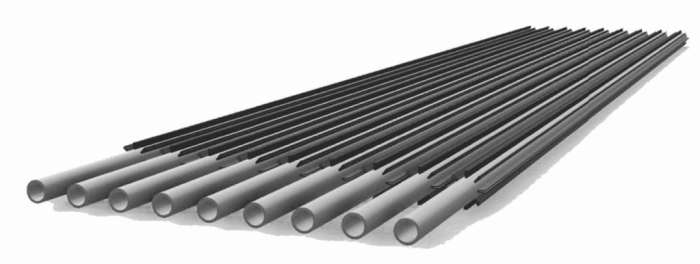

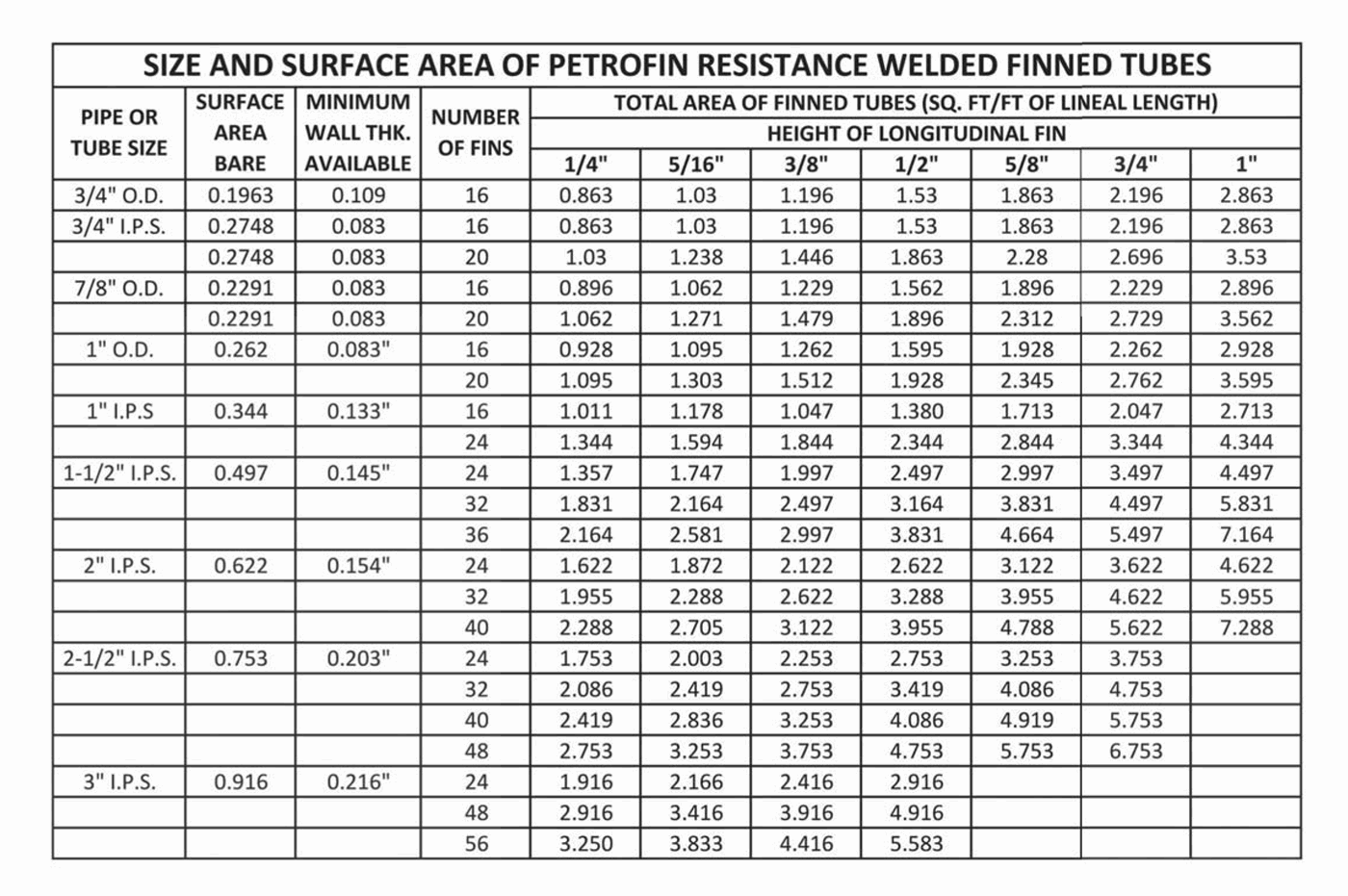

PETROFIN® Tube Data

Petrofin resistance welded longitudinal finned tubes are manufactured in a wide variety of materials, fin heights, and fin configurations. The table below lists our standard finned tube data; other combinations are available on request.