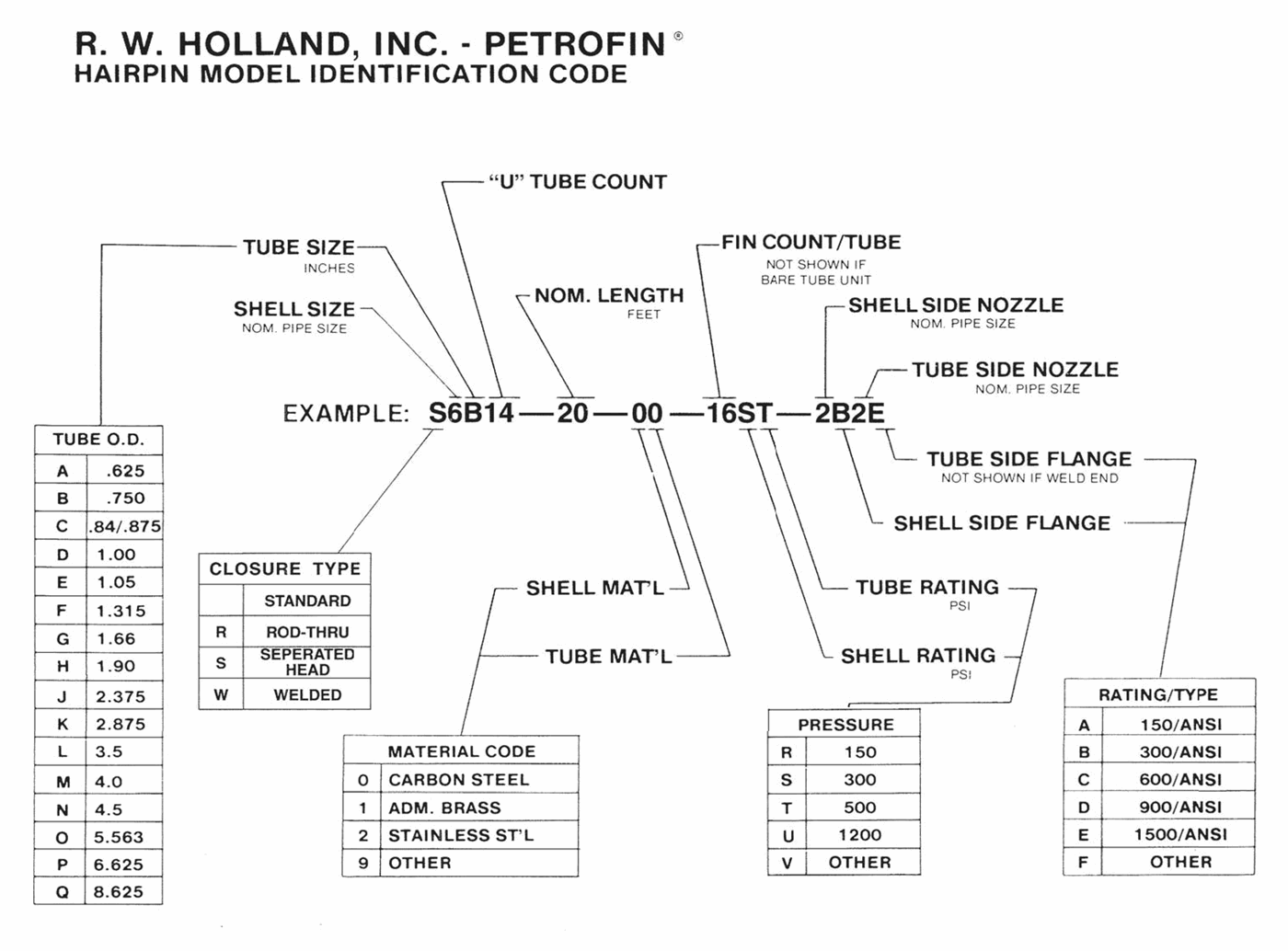

Bulletin 10: Hairpin Heat Exchangers

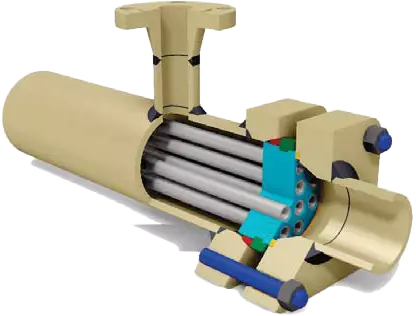

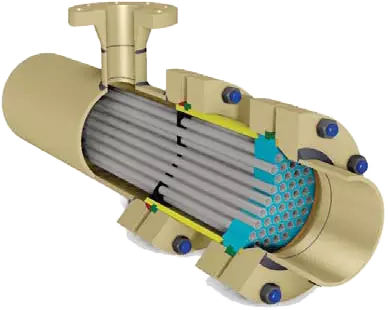

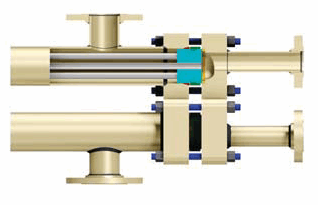

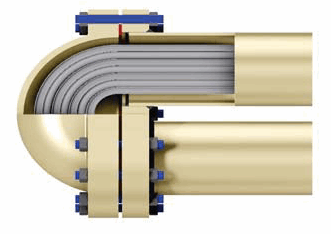

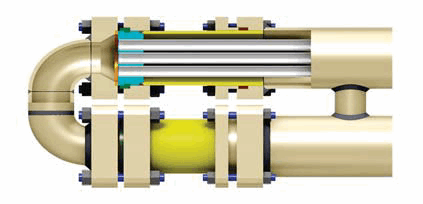

PETROFIN® Patented Closure

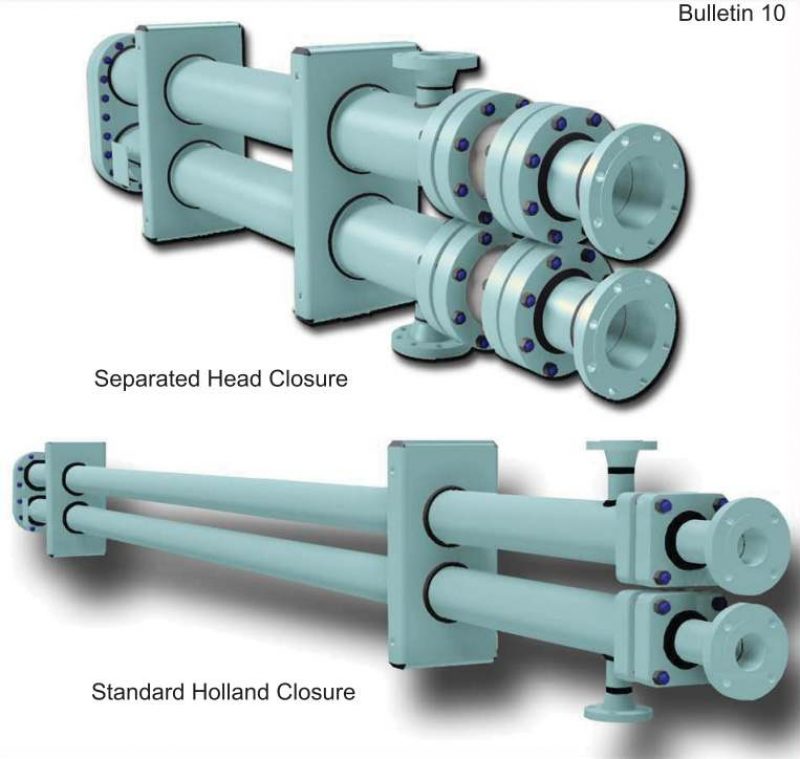

The Holland Petrofin Closure

- The Holland Petrofin closure has fewer parts, is the simplest to install and disassemble, and is the most efficient seal on

the market. Only two flanges are needed to secure both shell and tube seals. No other manufacturer does this with comparable results. - With one expendable seal for the shell side and one expendable seal for the tube side, there is an absolute guarantee against interstream leakage.

- There is only one reusable locking split ring that is in full view and is the simplest of all to remove and install.

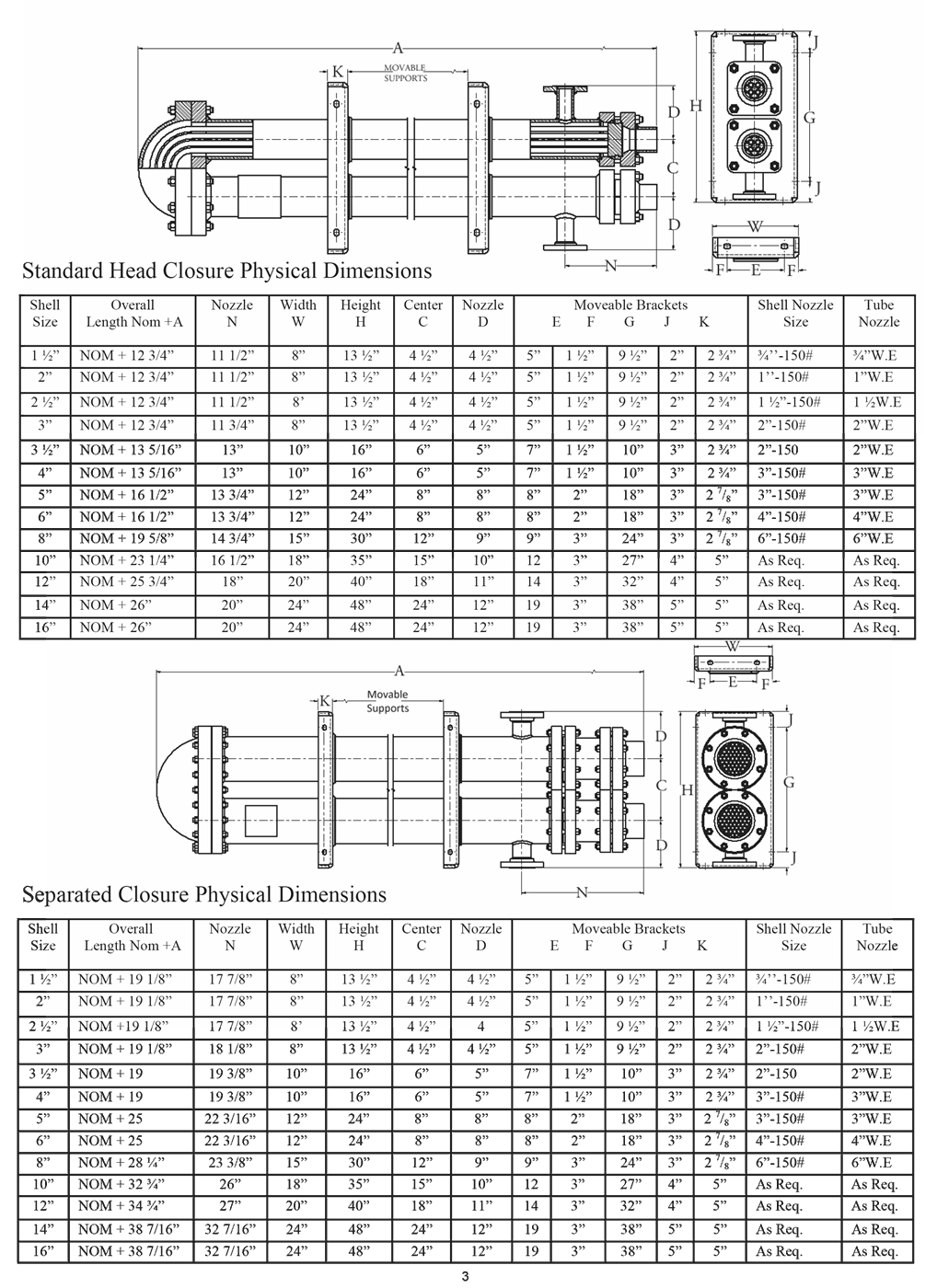

- Closures flanges on low pressure units up to 6” shell size area a square, 4 bolt design. Larger units and high pressure smaller units have circular closure flanges with additional bolting. Through-bolted closures are not standard on 6” and smaller units, but are available upon request.

- Tube bundles are easily removed and do not require disassembly of either the shell piping or mountings. Only five standard interchangeable replacement parts are required for reassembly after routine cleaning and maintenance. These are the rear cover gasket, sealing rings, and tube gaskets. Most sizes are stocked for immediate replacement.

- Our unique closure allows for more tubes in a given shell size resulting in more heat exchange for the same competitive price.

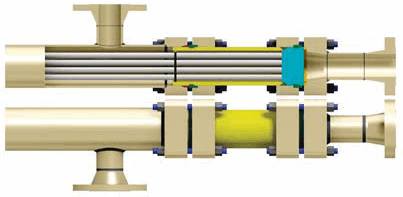

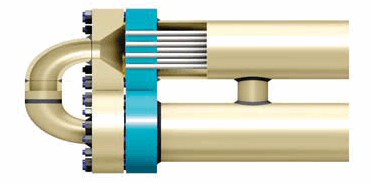

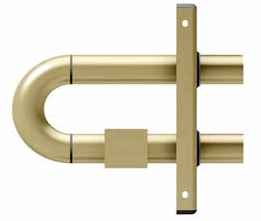

Separated Head Closure

The Holland Separated Head Closure

- The Holland Separated Head Closure has separate flanges and bolting for each sealing surface.

- With one expendable seal for the shell side, one expendable seal for the tube side, separate flanged and bolted joints for each sealing surface, this closure can handle all applications in severe service.

- This closure is recommended for pressures above 2000 psig, cyclic services, low temperature service, extreme temperature differentials and hard to hold fluids.

- Tube bundles are easily removed and do not require disassembly of either the shell piping or mountings. Only five standard interchangeable replacement parts are required for reassembly after routine cleaning and maintenance. These are the rear cover gasket, sealing rings and tube gaskets. Most sizes are stocked for immediate replacement.

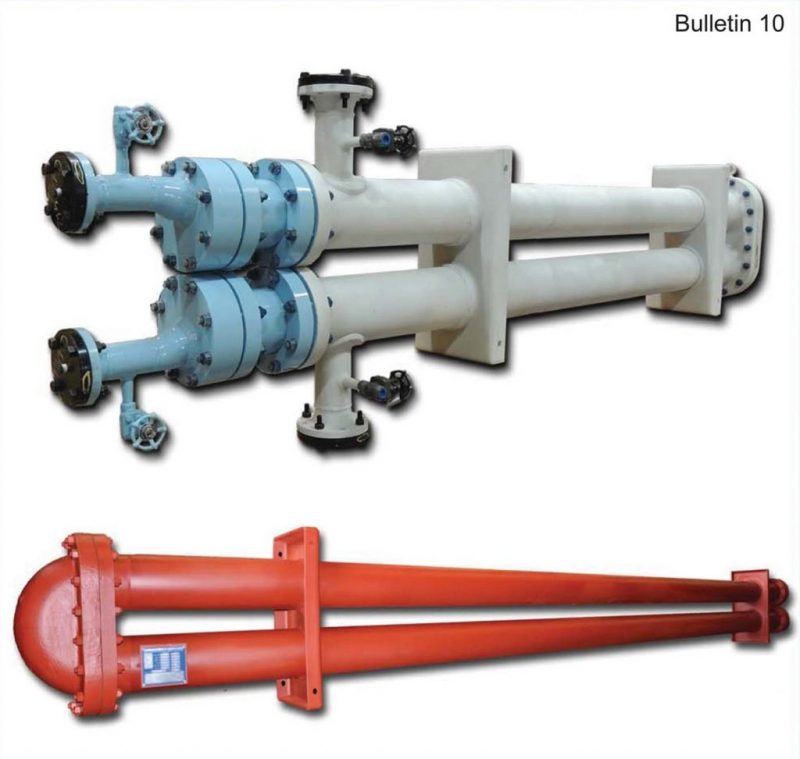

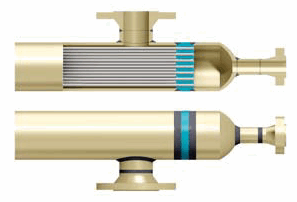

The Holland Hairpin Heat Exchanger

- All Holland hairpin heat exchangers are ASME inspected, code stamped and National board registered.

- Multiple sections can be shipped completely assembled and ready for one inlet and outlet process piping connection.

- Our longitudinal fintubes are produced by an electric resistance welding method, which assures high-heat transfer efficiency throughout the life of the equipment.

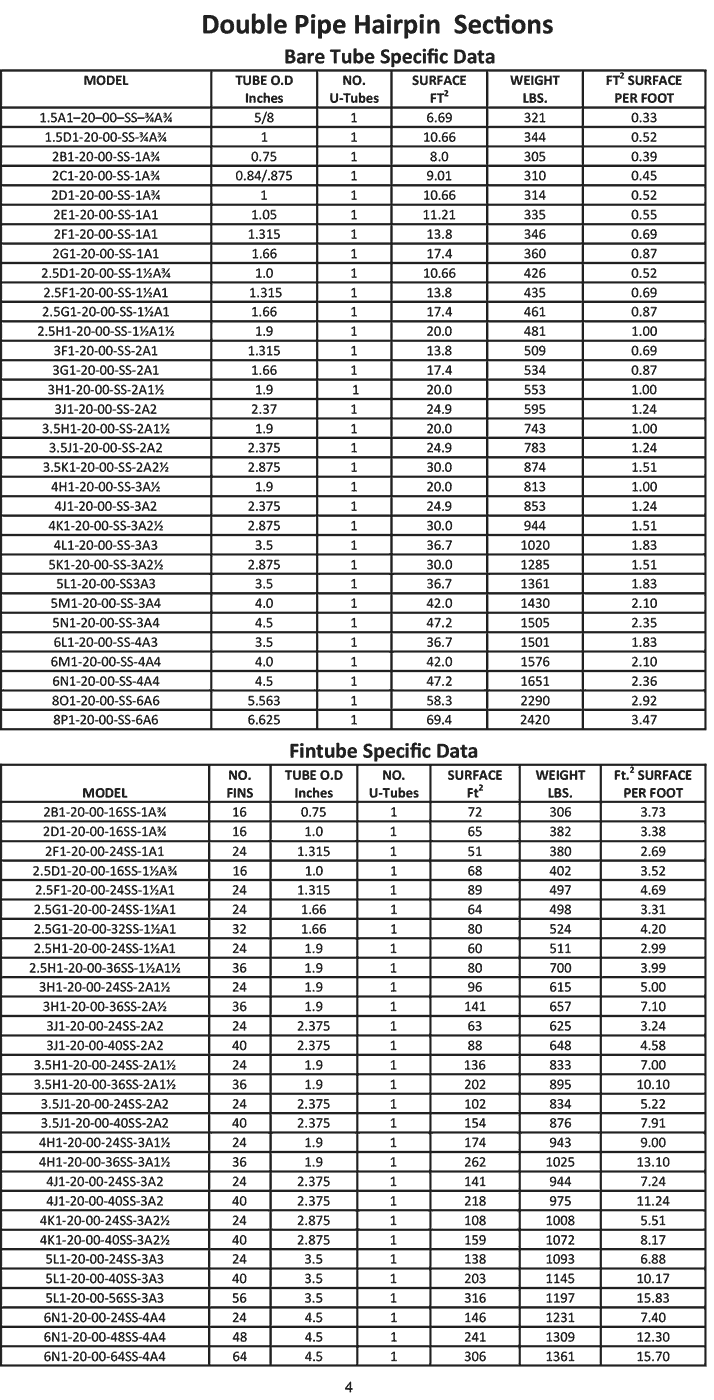

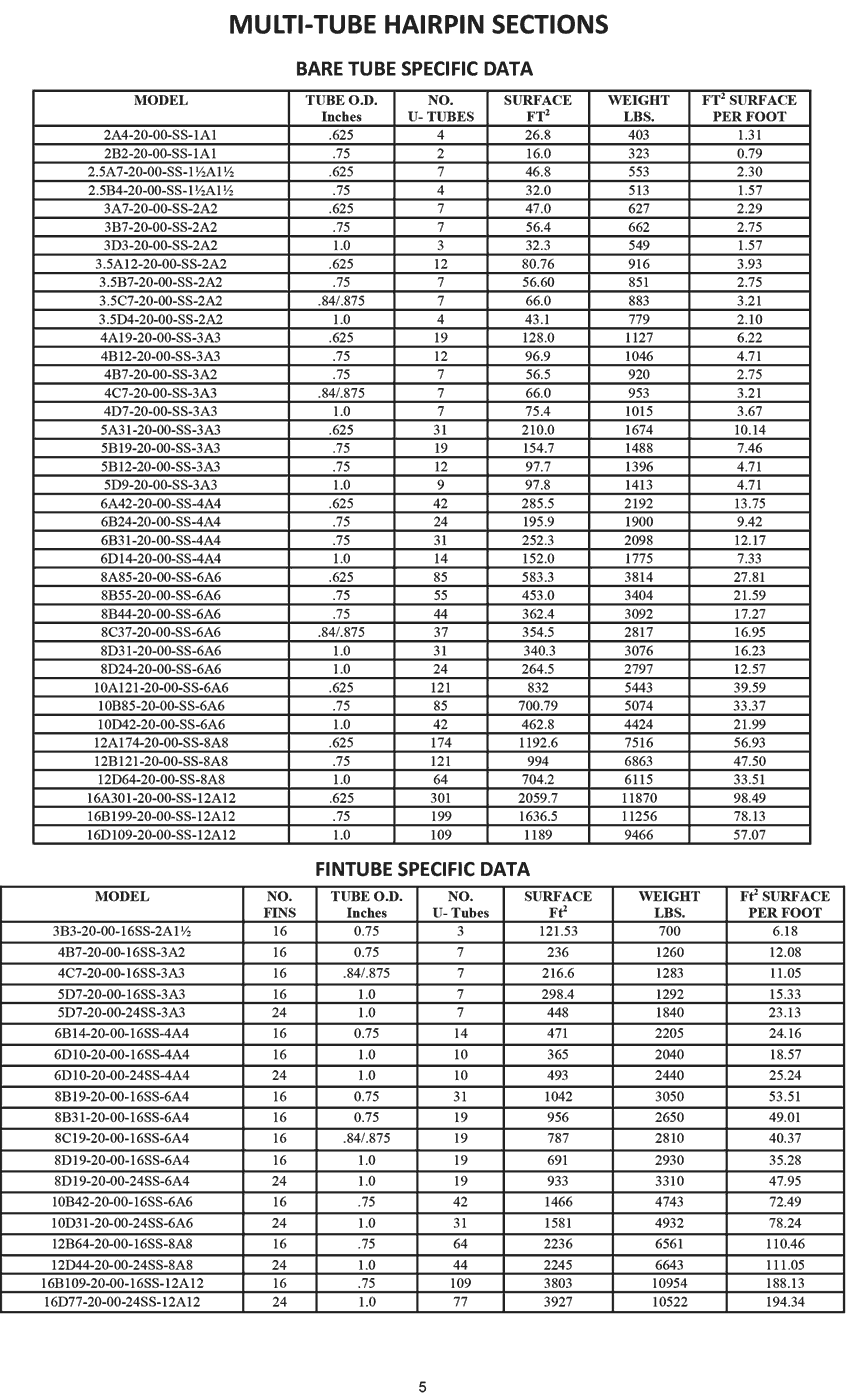

- Holland hairpin heat exchangers are available in a wide range of sizes to meet most process requirements. See pages 4 and 5 for the many standard design double pipe and multi-tube hairpin exchangers which are available.

- R.W. Holland’s standard designs reduce costs of engineering, thermal design, drafting, and shop fabrication. Although we offer standardized designs whenever possible, we custom engineer equipment to meet process or piping requirements. A few of our customers modifications are shown in this brochure.

Advantages of the Hairpin Heat Exchanger

- There are two types of hairpin heat exchangers.

- Double pipe section with one tube, either finned or bare, within the shell pipe.

- Multi-tube section with smaller tubes, either finned or bare, within the shell pipe.

- Hairpin heat exchangers operate in true counter current flow permitting extreme temperature crossing. The full log mean temperature difference can be utilized without reducing correction factors generally necessary in shell and tube exchangers. The larger temperature difference decreases surface requirements and cost.

- Due to their modular concept, hairpin heat exchangers are economically adaptable to service changes. Changing duties are met by merely rearranging, adding, or subtracting sections. Shell and tube exchangers frequently have to be scrapped and new exchangers ordered when duties change.

- The hairpin exchanger is ideal for wide temperature ranges and differentials. Because of the U-tube construction, expensive expansion joints are not required. Hairpin heat exchangers are not susceptible to tube-to-tubesheet weld cracks due to thermal stress. The thermal gradient of a tubesheet on a hairpin heat exchanger is through the thickness of the tubesheet as apposed to across the tubesheetface, as in multi-pass shell and tube exchangers.

- Hairpin deliveries are shorter than shell and tube due to the standardization of design and construction.

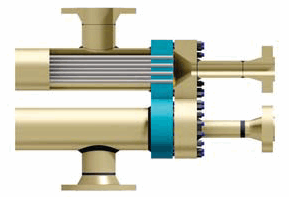

R.W. Holland Offers Flexibility to Meet Customer Applications And Specifications

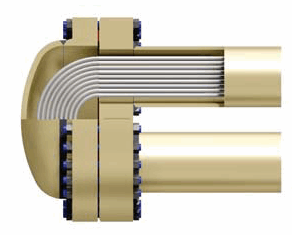

Tube End Closures

Holland standard closure. Tube nozzles can be offset for venting and draining. ANSI flange connections

Fixed tubesheet design, non-removable channel.

Holland separated head closure. Separate flanges and bolting for each gasket surface.

Fixed tubesheet design with removable channel for tube inspection.

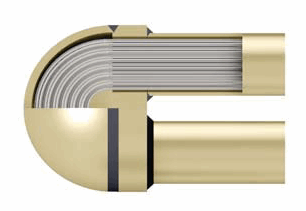

Return End Closures

Holland standard closure. When casting is removed, tube returns are completely exposed

Rod thru design with fixed tubesheets allows straight thru cleaning of tubes. Expansion joints furnished when required.

Welded closure for all welded design units using elliptical or hemispherical heads.

Fabricated closure for high pressure and alloy design where standard closure is not adequate.

Rod thru design with packed joint which allows straight thru cleaning of tubes and removing bundle.

Welded closure for all welded design using a 180 degree return.